Zheheng steel is one incorporate of manufacturer, Exporter

,consultant ,stockist company specialized in the area of stainless

steel tubing , pipe fittings ,Flanges and other stainless

steel grade accessories . It is one-stop-shop company ,our team

have more than 20 years experience in stainless steel field

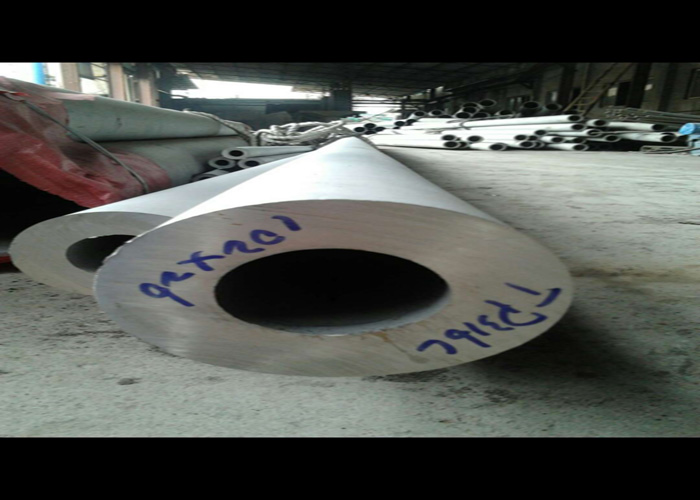

,especially in heat exchanger tubing and large diameter pipes with

ultra-long, ultra-thin, ultra-thick or ultra-large various and some

special-purpose projects .

After years of efforts,we now became more and more stronger , we

have consist of four company respectively located in

wenzhou(headquarter),lishui,chengdu city,two factorys of ss

stainless pipe workshop in lishui ,another one ss pipe fittings

workshop located in wenzhou ,one domestic sales company located in

chengdu.

On Time, On Budget, For Over 20 Years

Our reputation is for providing competitive prices, technical

services and on time deliveries for every project for over 20

years. Our inventory is computerized so our employees can respond

quickly to all your requests. If a specific product is not in stock

when you request it, we guarantee same day shipping or shortest

lead time available.

Our regular feture products are 304/304L,316L, 321,310s,austentic

serious ,duplex steel 2205 ,hastelloy c276,inconel 625 ,and super

stainless steel 904L , All of our products meet or exceed AISI/ASTM

A213 ,A269,A312,EN 10216,GHOST 9941 ,GB,JIS standard. per your

specific requirements and include full documentation.

More photos about our workshop :